Eddy Jet 2W Automatic Spiral Plater | Spiral Plating

The Best Spiral Plater just got Better! Quicker, Quieter and more Robust!

Description

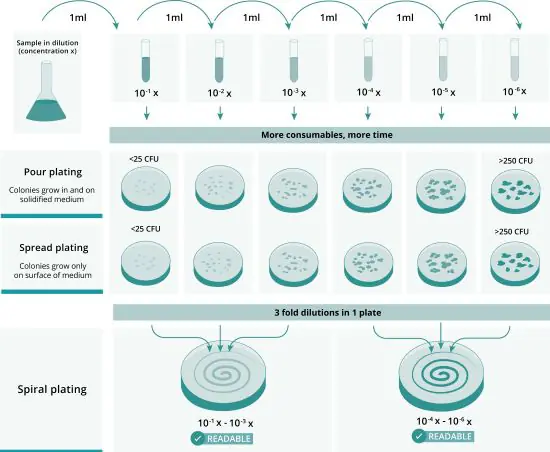

The spiral plating method has been validated as an effective method for the enumeration of microorganisms. This process enables the automatic and standardized sample plating and allows up to 3 dilution series on one Petri dish. This technique provides quantitative results over a wide concentration range while eliminating multiple dilution and plating steps, making it a cornerstone tool in modern microbiological analysis for pharmaceuticals and food safety.

The sample is plated in a form of an increasingly dilute spiral (outwards from the center). The volume is calibrated and known at every point of the Petri dish. This allows precise volume calibration and detection at every point, standardizing bacterial plate counts and streamlining bacterial enumeration. It is a vast improvement in speed and accuracy over manual methods. The Eddy Jet 2W Spiral Plater, advances this automated technology even further.

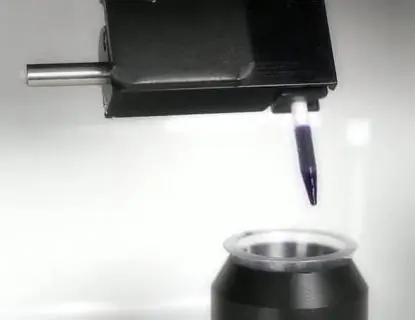

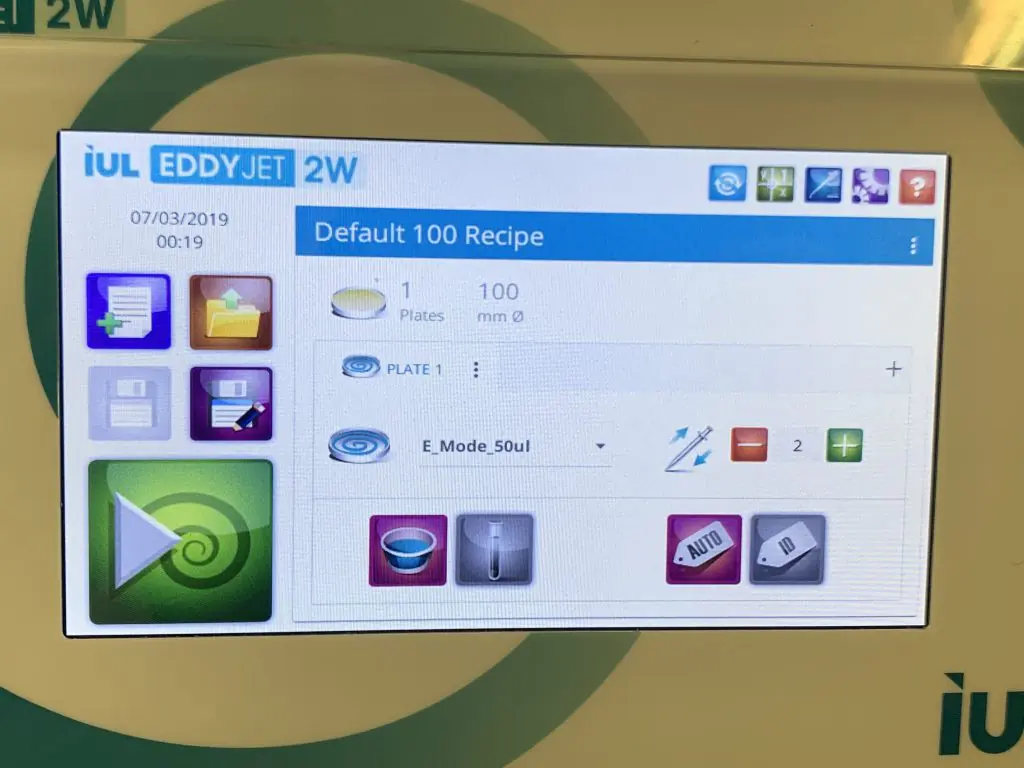

The Eddy Jet 2W Spiral Plating System is a large color, touch-screen fully programmable spiral inoculation instrument with accuracy and reproducibility of greater than 99%. The Eddy Jet 2W Spiral Plater uses a unique gamma-irradiated disposable micro-syringe for each new sample, eliminating cross-contamination and the need for a vacuum source or washing steps.

Since the samples come in contact only with the disposable low cost micro-syringe throughout the process, there is absolutely no risk of carryover of sanitizing chemicals, such as hypochlorite.

The tips are supplied with fully traceable quality control documentation. These sterile, precise micro-syringes (with opening size of 0.7mm) are your keys to confidence that you’ll get an accurate inoculation and no contamination on every plate that you process with the Eddy Jet 2W Spiral Plater.

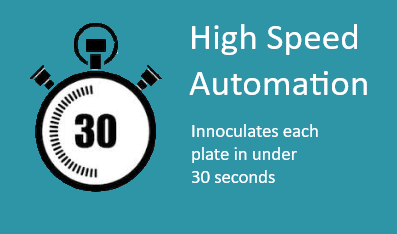

Significant savings can be made in material costs and workers’ time by using the Eddy Jet 2W Spiral Plater. Plates are processed in well under 1 minute; no time-consuming washing cycle; no time-consuming preparation and replacement of washing chemical solutions; no time-consuming maintenance of a vacuum pumping system; no downtime due to vacuum failure.

For Spiral Plating official methodology as stated by the FDA Bacteriological Analytical Manual (BAM) click here

Additional information about why your laboratory should use an Eddy Jet can be found here, and additional information about serial dilution can be found here.

See what our customer, food microbiologist, Kelsey Lamb has to say about the Eddy Jet 2W here.

The Eddy Jet 2W automates spiral inoculation with unparalleled ease, meeting the Association of Official Analytical Collaboration International (AOAC) standards for the consumables and agriculture industries.

Check how Spiral plates can be counted using Manual colony counter or automatic colony counter – The SphereFlash® – The SphereFlash® counts the majority of colonies on the various media. Its high-resolution color camera can detect and count colonies of approx. 1/450 inch (0.07mm). The new patented illumination device enables processing of any media type, including transparent/opaque agar, without interference from an ambient light source as the sphere goes down and creates an isolated environment. The SphereFlash® automated colony counter modular approach enables laboratories to automate their colony counting processes, inhibition zone measuring, and upgrade them to a higher level of sophistication as necessary, within a budget.

Many Eddy Jet 2W efficiencies include: reduced costs per test, less hands on time, and consumable use during counts all while increasing the microbiology lab’s productivity. This state-of-the-art spiral plater automates, standardizes, and streamlines plate inoculations due to its patented cross-contamination-free technology. Microsyringes provide the system with unique, unmatched advantages that make it a very popular laboratory device. This is partly due to the spiral plater’s ease of use. The user interface is very intuitive and there are no setup times. Unbox and set up your Eddy Jet 2W and it is ready to go!

Primarily in use by the consumables, cosmetic, and pharmaceutical industries in their research and development labs, any microbiology lab can greatly benefit from using the Eddy Jet 2W. This superior spiral plating device will generate a threefold dilution concentration gradient on a single plate. This allows labs to skip serial dilutions and most platings. To achieve the greatest accuracy, each sample is processed with a brand new sterile microsyringe, thereby making sample handling a cross-contamination-free process.

A capsule summary of improvements to spiral plating procedures using The Eddy Jet 2W include:

YES:

- Highest precision & accuracy: Results are more than 99% accurate

- High confidence in results: Provides highly accurate counts, minimizes/eliminates contamination, increases efficiency.

- Programmable: Enables laboratory personnel to multi-task thereby creating more efficient operative workflow.

- Very dependable: Increases reproducibility and greater overall cost savings.

- Preprogrammed modes: Contribute to greater operational efficiencies.

- Extremely easy to use: No learning curve – user interface is very intuitive and there are no setup times. Moreover produces high quality, easy to read/interpret plates. Combines ease of use and process innovations that offer measurable time and cost savings.

NO:

- Wash cycles: Unique feature eliminates need for washing steps.

- Concerns about carryover: Disposable micro-syringe prevents carryover contamination from sanitizing materials.

- Chemical/bleach solutions: Eliminates need for daily bleach solutions.

- Noisy vacuum pump: Does not utilize a vacuum pump.

- Vacuum failure downtime: Unique micro-syringe eliminates both cross-contamination and the need for a vacuum source.

Compare our Eddy Jet 2W to other Spiral platers

Eddy jet 2W | Others | |

| Disposable Irradiated syringe | √ | X |

| No Nozzle that tend to jam | √ | X |

| No risk of cross-contamination | √ | X |

| No need to prepare fresh bleach / water solution each day | √ | X |

| No risk of false results | √ | X |

| No use of Bleach Ethanol for the wash cycles | √ | X |

| No Noisy vacuum pump | √ | X |

| Reproducibility / Accuracy | ±1% | ? |

Features and Benefits

No use of bleach

Disposable syringes will prevent cross contamination

No “Down Time” due to washing of the tip (disposable)

Increases lab productivity by applying automation

Innovative large touch screen with intuitive icon operation

Ease of use and programming and creating pre-set protocols (NEW !)

Reliable and robust design for years of operation

Knowledgeable application support programs

Bar Code, Network compatibility

IUL Instruments leadership position backed by 30 years of experience and excellent reputation

Technical data

| Maximum Syringe Volume | 100 µl |

| Maximum Flow Rate | 50 µl / sec. |

| Minimum Step Volume | < 0.1 µl |

| Reproducibility | < 1% |

| Spreading Modes Stored | all the accepted |

| External Balance Connection | serial RS232 |

| Printer Connection | serial RS232 by IUL |

| Mains – self detecting | 110/220 VAC, 50/60 Hz. |

| Power | 120W |

| Dimensions (WxHxD) | 20.3″ x 16.8″ x 17.3″ |

| Weight | 44 lb. |

Ordering Info

| Eddy Jet 2W. Complete with 1000 syringes and 1000 sample cups. | CAT. NO. 90003800 |

Ordering Info Disposables

| Tips/Syringes. Pack of 1000 in boxes of 10 for the use with the automatic feeder. | CAT. NO. 90001780 |

| Cups. Pack of 1000 disposable. | CAT. NO. 90001790 |

| Tips/Syringes and cups are Sterile (irradiated with gamma-rays) | |

Spiral Plater FAQ

- How does a spiral plater work?

This automated process allows for plating multiple dilution ranges on a single dish. When liquid is dispensed onto its rotating surface, a spiral plater creates a spiral pattern on a Petri dish. Spiral platers are used extensively in the pharmaceutical and food safety industries. They save time and increase productivity by reducing the number of dilution and plating steps. - How do researchers count a spiral plate?

There are two ways to count a Spiral plater- Researchers can count colonies manually, using a grid to assist them. Or they can use an automatic colony counter, which not only speeds up the process, but provides researchers with far more accurate colony counts than manual counting processes. - What is the spiral inoculation method?

This method is known as “Spiral Plating”. Using a Spiral plater It is a technique that automatically spreads a sample in a spiral pattern on a Petri dish, allowing for standardization as volume can be calibrated at every point on the plate as well as increases throughput, thereby reducing the need for intermediary dilutions. - How is a count on a spiral plate performed?

Spiral plater counting is performed by counting the colonies on the plate after incubation, then calculating the bacterial concentration in the sample. Its advantages are that it is highly reproducible, requires fewer supplies, requires little training, is faster, and gives higher counts than the pour plate method. - What is the spiral inoculation method?

Spiral Plating is the technique using a Spiral plater that automatically spreads a sample in a spiral pattern on a Petri dish. Its benefits include: standardized plating for easier volume calibration, increased throughput and reduced consumable use, allowing rapid plating as plates can be inoculated in about 8 seconds. - What is the principle of spiral plating?

Designed in 1973 at the FDA by Dr. Ed Campbell, the Spiral Method uses a spiral plater to automatically deposit a sample onto a rotating Petri dish, creating a logarithmic spiral pattern. It is used in the pharmaceutical industry and for food safety testing. This method saves time and resources as it eliminates additional dilution and plating steps.