Agar/Media Filler PS20

A flexible agar petri dish filler for small batches which automatically fills and stacks small batches of petri plates. Easy to operate and clean!

Description

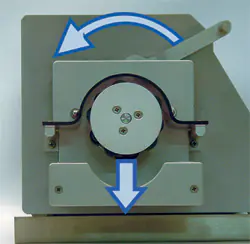

A flexible agar petri dish filler for small batches which automatically fills and stacks small batches of petri plates. This petri dish filling system is easy to operate and clean! Among its highlights, BioTool’s PS20 media filler fills 20 dishes directly into its PetriRack in less than two minutes. There is no need for manual stacking or any other manual operation. The filled dishes are safely stacked in the PetriRack and can be transported, chilled or incubated in the rack. Additionally, its fully autoclavable rack means that the dishes can be taken from the rack continuously. New rack = new batch! With this compact laboratory solution, BioTool has responded to frequent customer requests for a more compact and yet flexible filling unit. It is ideal for the production of small, special-purpose agar batches.

Despite the compact size, this smaller filling system solution does not disappoint. It is a fully automatic, very precise Petri dish filling system. Nor is it in any way deficient to larger models relative to pump delivery, operator prompting or software options. The PS20 provides ease of use applications that include dish feeding, single dosing, stacking, and dish discharging. Perhaps the chief value of the PS20 petri dish filling system is that it delivers precisely automated operations to enhance the productivity of your laboratory and potentially to reduce overhead.

Biotool Swiss is a brand that prides itself in applying the latest product technologies meant to increase media kitchen productivity. Neutec Group has been proud to provide their innovative agar plate filler systems to our customers throughout North America. This compact footprint media filler (PS20) is recommended for smaller lots, of 20 plates per batch. It is highly recommended for pouring small or special-purpose agar batches. It was designed to be far more flexible, versatile and user friendly than petri dish filling systems that utilized carousel petri dish fillers. It offers users state-of-the-art agar filling technology, including optional text/barcode label printing, changeable options for dish height stacking. The PS20 fills 20 dishes directly in the Petri rack. This means that there is no need for additional manual stacking at either end of the process. This petri dish filling system has been engineered for batch, or continuous operation with minimal downtime.

Biotool Swiss’ PS20 media filler is a unique laboratory solution that has been developed for customers who require a compact, yet more flexible-filling unit.

The media filler is now compatible with: 90mm and 60mm plates diameter and 15 and 25mm deep plates!

Agar/Media Filler PS20 Features and Benefits

Ease of operation includes software guides for smoother transitions

Allows for freely selected (1 to 20 dishes/stack) dish stacks to accommodate required height stack

Petri Dish Filling System accommodates any beveled edge / automation plates

High sterility at pouring area due to well-positioned UV light that includes a safety switch for increased reliability

Dual head pump creates smoother agar plates

Anti-drop mechanism prevents repels of agar

User-friendly touch screen allows for ease of use

Ergonomic design allows easy access to facilitate cleaning process

Occupies a compact footprint to fit any bench space

Technical data

Electrical data

| Parameter | Value | Remarks |

| Supply Voltage: mains voltage | 85 – 132 VAC and 176 – 264 VAC | 47 – 63 Hz. |

| Power Consumption | 40VA | |

| Mains Fusing | 250VAC / 3.15A Slow – Blow |

Mechanical data and environment

| Parameter | Value | Remarks |

| Dimensions LxWxH Unpacked | 20.47 x 15.74 x 24.4 Inch | 52 x40 x 62 cm |

| Dimensions LxWxH Packed | 24.4 x 16.53 x 27.16 Inch | 62 x 42 x 69 cm |

| Weight Standard 90mm | 40.7 / 60.9 Lb | Unpacked / Packed |

| Weight Standard 60mm | 40.7 / 60.9 Lb | Unpacked / Packed |

| Weight Standard 60/90mm | 52.8 / 77 Lb | Unpacked / Packed |

| Ambient Temperature | +5ºC to 45ºC | Also during transport. |

| Support | Sturdy support surface with a load-bearing capacity of at least 50 Kg. | |

| Sound Pressure Level | ||

| Pollution Severity | II | |

| Safety Class | IP 21 |

Performance Parameters

| Parameter | Value | Remarks |

| Suitable dish Diameters | 89 – 96 mm. | |

| Suitable Dish Heights | 14 – 20.5 mm. | |

| Dosing Quantity | 1.0 – 99.9 ml. | |

| Dosing Accuracy | Approx. 2% | |

| Delivery Rate | Approx. 800 ml. / min. | |

| Filling Capacity | 20 Dishes / 1.5 min.(15 ml) | |

| Filling Cycle Delay | 0.5 – 9.9 Seconds | |

| AntiDrop | 0 – 1.0 seconds | |

| UV Contamination Safety Lamp | 253.7 nm. (0.6 Wuvc) | |

| Direct Dish Throughput | Yes | |

| Quantity of Dishes per Stack | 1 – 20 Dishes per Stack | |

| Graphic Display | 240 x 128 Pixels | With led backlighting |

| Footswitch (Option) | The footswitch contacts are designed as normally open contacts (NO contacts) | |

| Interfaces (Option) | RS232 RS485 | Connection to host BioLink (laboratory device communication) |

| Item Number PS 20 Standard 90mm | 800.000 | |

| Item Number PS 60 Special 60mm | 810.000 | |

| Item Number PS 60/90 Combo | 810.000 Co |