In a food microbiology laboratory, daily counting of microbial populations in food is a standard procedure. This makes bacterial colony counting procedures, part of microbiology laboratory workflow, requisites. Increasingly, colony counting and rapid plating methods are being utilized by a greater number of microbiologists in their daily work routines. Counting colonies is an essential task, however it is very tedious and manual counts can easily be inaccurate. Since the manual colony counters’ enumeration process is extensive it can therefore also be very slow. Some reasons for inaccuracies are because the colonies themselves can often be very small, or may be disguised by the culture medium’s specified color. A more expeditious process is necessary to optimize these daily routines to save time, increase accuracy, as well as productivity. Efficient automatic colony counters offer an ideal solution.

Currently, there are different methods available for determining the number of colonies (CFU) in a sample of food, drug, or water. From a given known volume sample count, the number of CFUs per plate to CFU per ml of bacteria culture or grams of sample, is extrapolated. The general formula to calculate CFU/ml is well known:

The number of microbes/ml = number of colonies x dilution of the sample.

Common Manual Colony Counter Methodology Issues

As noted in the FDA BAM (Chapter 3), the appropriate colony counting range is 25-250 colonies per plate. Plates that exceed 250 CFUs are too numerous to count or may additionally inhibit some bacterial growth.

Conversely, plates with fewer than 25 colonies are not considered sufficient or statistically representational of the sample analyzed. To obtain optimal spread plating results, prior to inoculating the plate sample, serial dilution of a minimum of three plates must be performed. NOTE: This range will vary based on the method employed.

Next, the plate will be incubated under conditions deemed appropriate for the microorganism after which time the colonies may be counted. If the spread, pour, or drop methodologies are employed, the colony counting will be self-evident: each colony dot is to be counted just once. Use a marker to point each counted colony on the back of the Petri dish.

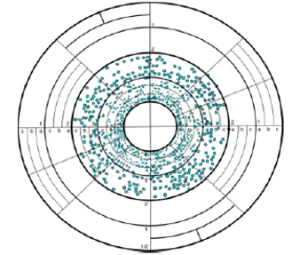

How would a colony counter work in conjunction with a spiral plate?

When counting a plate which has been spiral plated, the spiral plating grid is divided into 8 equal sections, which are then divided into 4 concentric rings. With 100 mm Petri plates,counting is restricted to the 3rd and 4th counting grid ring sections only. In 150 mm plates only 1, 2, 3, and 4 ring sectors are counted. Each ring is again divided into three rings (3c, 3b, 3a, and 4c, 4b, and 4a).

The colony counting is performed within these ⅛ sectors of the counting grid’s rings. It is necessary to begin counting at the outermost grid ring inwards towards the center. When a sufficient colony count is achieved, counting can be resumed until the entire number of colonies within this same ring sector have been counted. At this point, it must stop. Continue by counting the colonies in the same rings or the opposite sector. Refer to the table provided with the Spiral Plater to note the dispensed volume in the ring where the count has been performed and the method used.

Follow this formula to quickly determine the CFU/ml:

CFU/ml = (N’ + N”) / (V/4)

N’ = CFU count in the first 1/8th ring sector = CFU

N” = CFU count in the opposite 1/8th ring sector = CFU

V = Volume of the corresponding space

Conventional Plate Methods vs Spiral Plate/Eddy Jet

When the three most conventional colony counter methodologies, pour plate, surface spread plate, and the drop count method, are juxtaposed against the spiral plate method, the disadvantages of the three methods become apparent. The chief disadvantage is the tedious, repetitive, exacting nature of this task. It is no wonder then, that for a long time, microbiologists have researched colony counters seeking an instrument that offers faster, more accurate counting techniques. Spiral testing offers that solution.

The Spiral plater, which is extensively used in the Food Safety Testing and Pharmaceutical industries saves time, resources, and is cost effective. It is also more accurate than manual colony counters. The spiral system allows microbial concentration estimates over a 3 magnitude order. For example, the IUL Eddy Jet spiral plater (sold by Neutec Group) features a single spiral and offers a detection range between 4.102 and 4.105 and is able to sow 50µl better, without having to repeatedly dilute the sample. By doing so, it uses only a single agar plate per sample.

The spiral plate method is the solution microbiologists have been looking for! It can readily replace any of the conventional colony counting methods for the measurable estimation of applicable microorganisms in foods.

Moreover, the colony counting speed can be greatly increased even further by using an automatic colony counter.

We invite you to transition from tedious, potentially inaccurate, and time-consuming manual colony counters to automated colony counting. Calculate your Cost Savings and Return on Investment R.O.I. Click here to view our calculator.

Our Solutions: The Dot and SphereFlash

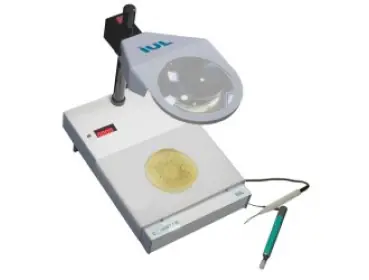

Colony counting is facilitated using IUL’s fast and easy to use colony counters featuring LED lighting. Excellent illumination in a colony counter provides greater speed and count accuracy. Its optimal light orientation reduces or eliminates inaccurate counts, thereby reducing artifacts, while increasing colony discrimination.

DOT: the use of a digital counter such as DOT can be useful for microbiology labs involved in colony enumeration. The operator can tick off detected colonies with a specifically devised marker, meanwhile a digital display will increase total counts. IUL’s DOT Colony Counter has a large 120 mm diameter lens with a DINx2 magnification power. The light can be adjusted to the needs of the user and accounts for surrounding light inside the laboratory.

The SphereFlash® – automated colony counterThe SphereFlash® – automated colony counter is scalable. It may be adapted to suit your microbiology laboratory’s specific requirements. The SphereFlash® is additionally upgradable by accessing different software tiers. These tiers are based on the level of automation, security and features that your microbiology lab requires. Neutec’s user-friendly SphereFlash® Colony Counter utilizes cutting edge technology including LED lighting and intelligent software to make the once tedious and inaccuracy prone task of colony counting faster and more accurate, and your lab more productive.

Moreover, studies comparing The SphereFlash®’s previous generation automated colony counter, The Flash and Go, concluded that the use of automated colony counters increased the overall efficiency of research operations. The advantages to using this automated instrumentation are significant time reductions over manual plate counts, as well as facilitated tasks for data manipulation, analysis, and its interpretation. The second generation automated colony counter, The SphereFlash® exceeds its predecessor’s standards to provide current state-of-the-art microbiology lab instrumentation.