June 22, 2021 – Scientist Live

Dr. Brady Carter discusses the new standard for water activity measurement

Water activity has been broadly used in the pharmaceutical industry since the publication in 2006 of USP <1112>, an informational chapter on the application of water activity in pharma. Although <1112> provided guidance for the utilization of water activity, it was not an official method. Now USP has developed USP <922> Water Activity as an official method that will hopefully further facilitate its implementation as an integral part of a pharmaceutical quality program.

There can be an abundance of confusion with water activity instruments concerning test time. Some instruments claim a 5-minute test time while others offer fast or quick modes. The truth is that water activity test time is determined by the sample and not the instrument. Since water activity is an equilibrium measurement, a reading is not complete until vapor equilibrium has been achieved and this process cannot be sped up by an instrument (1). So, any claim to a specific test time is illogical and would only be true for select samples. The reality is that most types of samples require a minimum of 5 minutes or more to reach true equilibrium and test times that are faster than that are either using a prediction or the system uses end-of-test settings that are not stringent enough to achieve true vapor equilibrium.

January 4, 2022 – Scientist Live

Dr. Brady Carter on modelling shelf life with water activity

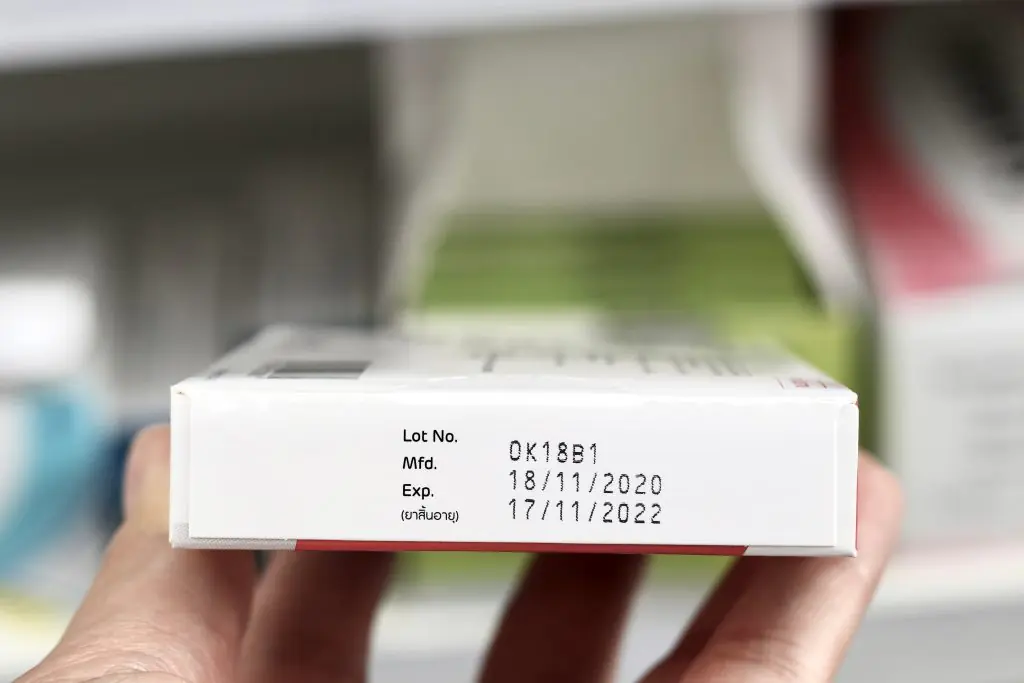

The shelf life of a product is defined as the practical time that it remains desirable to consumers. It dictates the radius of distribution for the product, how it must be stored and its best by date. Failure to match this expected shelf life can result in customer complaints, product recalls and tarnished reputation. Consequently, correctly determining the optimal production process and handling that maximizes the shelf life and then monitoring to make sure those conditions are met is the difference between profitability and lost revenue.

Water activity testing, gauged by using a water activity meter, is most often used to determine the shelf life of a food product. It is important to gauge the amount of water in a food as it is known that water activity above 0.95 a w will provide sufficient moisture to support the growth of bacteria, yeast, and mold. Because it predicts stability relative to microbial growth, their rates of deteriorative reaction, and physical properties, water activity is considered to be an important property in the field of microbiology. In fact, regulatory agencies such as the Association of Official Analytical Chemists (AOAC), International Organization for Standardization (ISO), American Society for Testing and Materials, (ASTM) United States Pharmacopeia (USP) and a host of American, Canadian and International governments, have incorporated water activity standards into their safety regulations. If the water activity of food is controlled to 0.85 a w or less in a finished product, it is considered regulation-compliant.

June 20, 2022 – Scientist Live

It’s the sample, not the instrument, explains Dr. Brady Carter

There can be an abundance of confusion with water activity instruments concerning test time. The truth is that the water activity test time is determined by the sample and not the instrument. Since water activity is an equilibrium measurement, a reading is not complete until vapour equilibrium has been achieved and this process cannot be sped up by an instrument. So, any claim to a specific test time is illogical and would only be true for select samples. Ultra-fast test time claims are based on either a prediction or end-of-test settings that are not stringent enough to achieve true vapour equilibrium.